The production process of LVL (laminated veneer lumber) begins with the careful selection of logs that meet the desired parameters. These logs are then subjected to peeling, where they are stripped of their outer layers. Following the peeling process, the veneer sheets are soaked and prepared for further treatment.

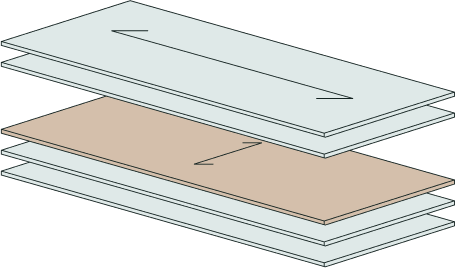

Next, the peeled veneer sheets are cut, dried, and sorted based on their quality and characteristics. This sorting process ensures that only the best veneer sheets are used in the production of LVL. Once sorted, the veneer sheets undergo an important step where they are applied with glue. The glue acts as a binding agent, providing the necessary strength and stability to the LVL product. The glued veneer sheets are then carefully layered, ensuring proper alignment and distribution of the wood fibers.

To achieve the desired strength and integrity, the layered veneer sheets are pressed together using a hot press. This process involves applying heat and pressure, allowing the glue to cure and bond the veneer sheets together effectively. The result is a solid and robust LVL panel.

After the pressing stage, the formed LVL panels are cut to the specific dimensions required by the customers. This customization ensures that the LVL products meet the exact requirements and specifications of each project. To prepare the finished LVL products for shipment, they are meticulously packed to ensure their protection during transportation.

The packed LVL products are then delivered to the customers at their designated locations, ensuring a convenient and efficient supply chain. Throughout the entire production process, stringent quality control measures are implemented.

Continuous monitoring and inspection ensure that each LVL product meets the highest standards of quality and performance. This dedication to quality control guarantees that every piece of LVL leaving our facility is of exceptional quality and reliability.