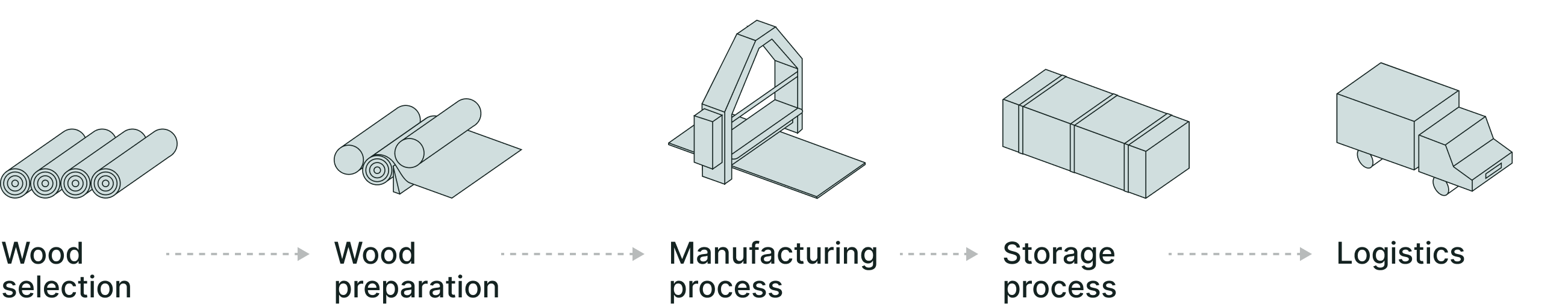

We select suitable logs for the production of particle boards. Once debarked, the logs are chipped into small pieces using specialized machinery. The wood particles are then dried to reduce their moisture content. This step is important as it ensures the stability and quality of the final product. The dried wood particles are screened to remove impurities and sorted according to size.

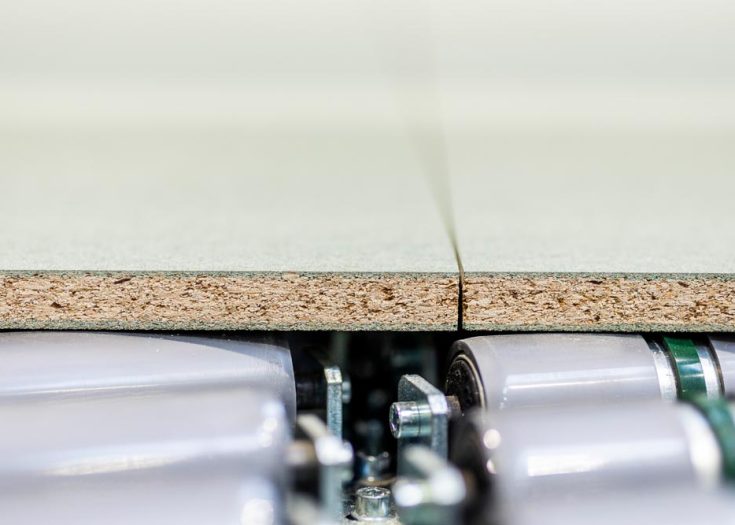

The wood particles are then mixed with a resin adhesive in a specific ratio. The mixture is then blended to ensure an even distribution of the adhesive. The resin-coated wood particles are spread out evenly onto a conveyor belt, forming a mat. The mats are compressed to remove excess air and ensure uniform density. The mats are then transferred to a hot press where they undergo high pressure and temperature. This process activates the resin adhesive, causing it to bond the wood particles together. The duration of pressing and curing depends on the specific product requirements and adhesive type.

After curing, the boards are removed from the press and trimmed to the desired dimensions. The finished particle boards are thoroughly inspected for quality control purposes. Defective boards are identified and separated from the acceptable ones. The approved particle boards are stacked and packaged in pallets for protection during transportation. The packaged particle boards are loaded onto trucks or shipping containers for delivery to customers or distribution centers. The boards are transported using appropriate logistics methods, ensuring safe handling and delivery to the designated locations.

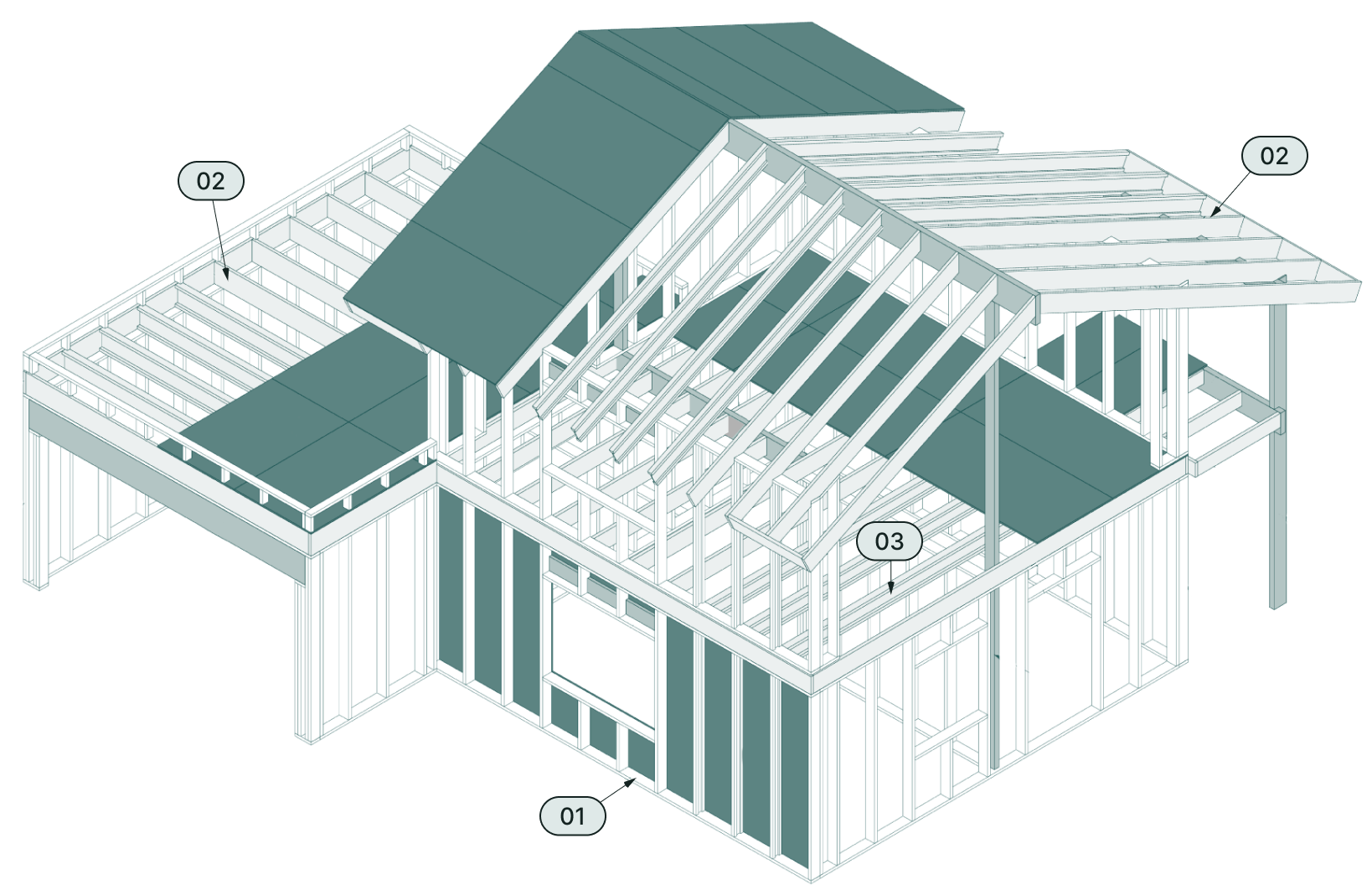

We manufacture T&G4, T&G2, and REGULAR type (P5 / P7) of moisture-resistant and load-bearing glued structural particle board. These products are an excellent alternative to the traditional OSB/3 and OSB/4 boards and can be used in service classes 1 and 2. In our product range, we also have VMG LIGNUM BOARD P4 and VMG LIGNUM BOARD P6 for use in dry environments.